ARMAS FERTILIZER TANK

APPLICATIONS

- Chemical fertilization applications by pressure agricultural irrigation systems

- Pesticide administration by pressure agricultural irrigation systems

FEATURES

- It provides ease of use and of maintenance due to simple structure.

- Pre-painting phosphorization is performed for maximum resistance against corrosion and chemical solution.

- It has long economic life based on Epoxy – Polyester coating.

- It operates based on line pressure of the system.

Armas 5000 series fertilizer tanks are developed for chemical fertilizer or pesticide applications directly to root region of the plant using irrigation water of drip or sprinkler irrigation systems. It ensures very practical and convenient fertilizing and pesticide administration in irrigation systems due to simple structure and ease of use. Different models with varying capacities are available including horizontal and vertical types depending on different needs of present irrigation system. Operating based on pressure difference principle in the irrigation systems, Armaş 5000 series fertilizer tanks will operate long years without requiring maintenance due to resistant construction.

|

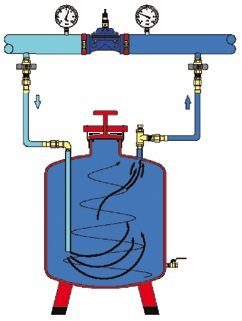

OPERATING PRINCIPLE

Armas 5000 series fertilizing tank is connected parallel to main pipe of irrigation system using elastic hoses via by-pass method. Irrigation water enters into the tank containing soluble chemical from the inlet hose of fertilizer tank connected to the line. Due to pressure gradient created using a valve or pressure reducer assembled on the irrigation line, chemical fertilizer is solved and it is blended within the tank. Solved chemical fertilizer is supplied to the root region of the plant using irrigation water.

|

![]() Download Product Catalogue

Download Product Catalogue