Armas Valves & Filters

Armas - Valves and Filters

ARMAS was founded in 1998 to produce valves for potable water and agricultural irrigation systems. It has become one of the leader establishments of its sector in a short time thanks to ARMAS makes valves.

ARMAŞ has given high quality services with economical prices to his costumers in industry, potable water networks and agricultural irrigation systems by means of Hydraulic Control Valves, Automatic Filtration Systems, Gate Valves, Ball Valves, Strainers, Check Valves, Air Valves and Hydrants he produced. Our company who does not sacrifice quality in production has used ISO 9001-2000 Quality Management System since 2000. In the scope of importance we gave for both human and environment, we have developed our institutional structure day by day with ISO 14001 Environmental Management System Certificate and TS 18001 Occupational Healthy and Safety Certificate since 2007. Our products have been subjected to pressure and performance tests before sales by Quality Control Department and technical support services have been given at the installation, operation and maintenance stages after sales by our experienced engineers.

ARMAS has continued R&D investments in order to present more quality and reliable products to his costumers, will continue its costumer-satisfaction focused services with increasing achievements in future thanks to his dynamic staff, powerful brand and permanent developing structure.

Mini Plastic Disc Filters

Go to product's page

| Body Material | : | Plastic |

| Internal Material | : | PP – PRGF |

| Maximum Working Pressure | : | 8 bar |

| Maximum Working Temperature | : | 60° |

| The Filtration Sensitivity | : | 130 micron |

| Cartridge | : | Disc |

| Made in | : | Turkey |

NZ $29.00 NZ $40.00

Mini Plastic Screen Filters

Go to product's page

| Body Material | : | Plastic |

| Internal Material | : | PP – PRGF |

| Maximum Working Pressure | : | 8 bar |

| Maximum Working Temperature | : | 60℃ |

| The Filtration Sensitivity | : | 130 micron |

| Cartridge | : | Screen |

| Made in | : | Turkey |

NZ $29.00 NZ $40.00

Hydrocyclone Sand Separator

Go to product's page

| Body Material | : | ST37-2 (DIN 17100) |

| Operating Pressure | : | 0.3-8 bar |

| Working Temperature | : | -10° C to 80° C |

| Connection | : | Flanged ISO 7005-2 or ANSI Threaded BSPT-NPT or Grooved End |

| Made in | : | Turkey |

NZ $983.00

Self Cleaning Suction Filter

Go to product's page

| Min. Working Pressure | : | 1.5 bar (22 psi) |

| By-pass Flow Rate | : | 4 m3/h |

| Screen Size | : | 5000 micron |

| Electrostatic coated body | ||

| Rotating Nozzles | ||

| Connection Type | : | Flange |

| Available Models | : | 4", 6" , 8", 10", 12" |

| Made in | : | Turkey |

NZ $1,850.00

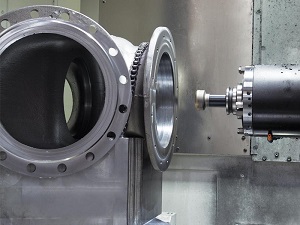

Automatic Self Cleaning Horizontal Filters

Go to product's page

| Body Material | : | St-37 – AISI 316L |

| Screen Material | : | AISI 304L – CAGEPRGF |

| Maximum Working Pressure | : | 8 bar |

| Minimum Output Pressure | : | 2.5 bar |

| Maximum Working Temperature | : | 60°C |

| Back Wash Time | : | Timing and Pressure Setup |

| Control System | : | Electric or Hydraulic Control |

| The Filtration Sensitivity | : | 100, 130, 200 micron |

| Paint Material | : | Epoxy polyester |

| Made in | : | Turkey |

NZ $5,666.00 NZ $6,360.00

Pressure Reducing Plastic Control Valve

Go to product's page

Pressure reducer control valve continuously controls downstream pressure value and maintains it without being affected by flow rate and upstream pressure values.

Easy to use

Low cost

Operation in wide pressure range (PN10)

Perfect modulation even in lower flow rates

Anti-surge closing and opening with flexible diaphragm

Glass Reinforced Poly-amide material

Made in Turkey

NZ $173.00

Min: NZ $28.00 Max: NZ $5,667.00

$28 $5667